News, Stories and Product Launches

Uniplex (UK) Ltd

The haemostat absorbing your cost pressures

Posted 31st July 2019

Hospitals have been using the same product for over 50 years, potentially overspending by thousands – it’s time to review your absorbable haemostats

The absorbable haemostat was invented over 50 years ago when scientists discovered that adding oxygen to plant-based fabrics caused complete absorption when placed in blood. Medical device companies used this discovery to invent, what was at the time, a clinical practise changing product.

It is now standard practice to use an absorbable haemostat in a vast array of surgical procedures, from minimally invasive to open surgery. Although the original haemostats from the 1960s are still functional in modern medicine, there have been vast advancements in product development and technology. Some hospitals and surgeons are yet to adopt the modern products, despite them being more effective than the original products and potentially cheaper.

Traditional absorbable haemostats are manufactured using regenerated absorbable cellulose (ORC), which is the chemical modification of cellulose. Modern oxidised cellulose haemostats are manufactured from premium quality, extra-long-staple cotton, therefore are natural products. Oxidised Cellulose (OC) haemostats have very similar characteristics and practically the same indication as oxidised regenerated cellulose, however, they differ in some properties that can be considered as important for their clinical use.

The Research

Independent research has been carried out comparing two types of haemostats, testing what is considered the key components of an absorbable haemostat. These include area density, structure, bio-resorbability, absorbency, pH level and (re)positioning. The two products used in the study were Okcel for the oxidised cellulose and a commonly used oxidised regenerated cellulose. The research paper compared and contrasted what is considered the main features of an absorbable haemostat and Okcel (OC) came out favourably in the vast majority of the experiments.

What the research says¹

– Okcel (OC) has a higher surface area than ORC, which directly leads to faster haemostasis

– OC has a higher fluid absorbency than ORC

– Okcel Heavy-Duty and Cotton Wool form has a lower Ph than ORC haemostats

– OC haemostats are easier to reposition than ORC, as they retain their original shape and size

– Okcel absorbs into the body faster than ORC

– Okcel has a higher area density than ORC, one of the factors that support fluid absorbency

Haemostasis

The main purpose of a haemostat is to stop unwanted bleeding during a surgical procedure, also known as haemostasis. There are several features that can affect haemostasis, including but not limited to, area density, pH level and absorbency. When testing these aspects, the research found that Okcel had a greater area density than ORC across the entirety of the Okcel range, with Okcel S (coming to the market in early 2020) having the greatest difference with almost double the area density from the same size piece of material.

The second feature considered was the pH level, as generally, a lower pH value has a positive effect on haemostasis. Okcel HD, F and S all had lower pH levels than their ORC counterpart, the only format that didn’t was HT, which was very similar at only 0.06 higher.

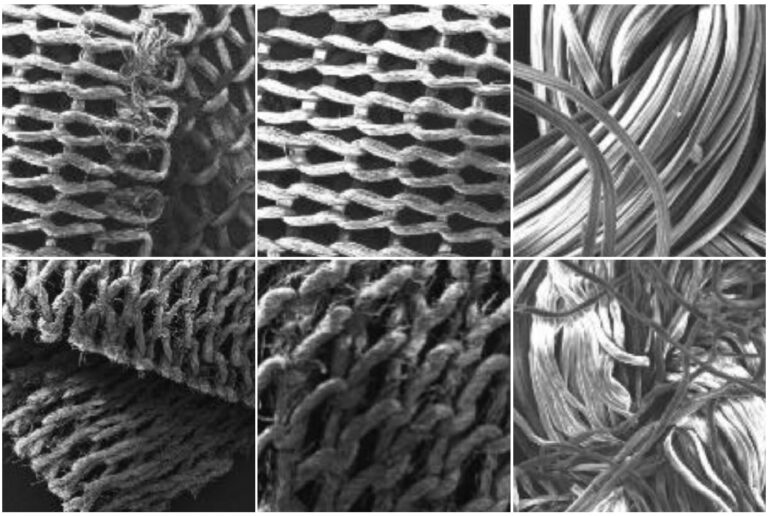

Arguably, the most important feature of any haemostat is absorbency, i.e. how much blood the products can actually soak up. Once again Okcel came out on top across the range. This can be attributed to the properties identified above in ‘what the research says’ and figure 1 below. Okcel offers a much more tightly knit material which increases area density and gives a higher surface area, allowing greater absorbency, thus contributing to faster haemostasis.

Okcel – The oxidised cellulose haemostat

Okcel is manufactured by Synthesia and is distributed by Uniplex (UK) Ltd. Okcel comes in three formats standard (HT), Heavy-duty (HD) and cotton wool form (F), with Okcel S, the woven form of oxidised cellulose to be released to the UK market at the start of 2020. Okcel products are available in the industry-standard sizes for simplified conversion. Okcel achieves haemostasis in under 3 minutes and if fully absorbed by the body within 21 days without any residue. The products have been used for over 20 years and utilised in excess of 3 million surgical procedures across the globe.

References

1. Jindřich Lahovský,(2019) Comparison of basic physiochemical parameters, USP parameters and mechanical and biological performance of regenerated and non-regenerated oxidized cellulose-based haemostats: A-Pharma s.r.o. contract research organisation, Study Report Ref. No.AP-SY-1901

Cost-effective haemostat to achieve savings for theatres

In this current climate, in which public spending is coming under closer scrutiny, Uniplex believes that a review of expenditure could prove useful and revealing for…

Sunoptic’s brightest LED headlight

The innovators at Sunoptic Surgical have launched their brightest battery-powered LED headlight to date – the SSL-9500. The experts in surgical lighting…

Partnership helps surgeons heal wounds

In the middle of 2016 a strategic partnership was formed between Meril Life Sciences and Uniplex UK Ltd to introduce a premium brand of absorbable and…